Designed for ammunitions

Our IMUs deliver exceptional robustness to shocks, vibrations and temperature variations. This makes them perfectly suited for precision guided munitions. Our performance range allows different applications, from industrial grade IMUs suited for control to tactical and high-tactical IMUs perfect for control and navigation.

Discover our solutions

Qualified for harsh environments

Our IMUs are designed to operate reliably in harsh environments. From the raw sensors to the electronics and mechanical integration, we make sure our IMUs can withstand the extreme conditions of a guided ammunition use case.

We thoroughly qualify our IMUs for harsh conditions, and we have the expertise and know-how to perform specific qualifications adjusted to the use cases of our most demanding customers.

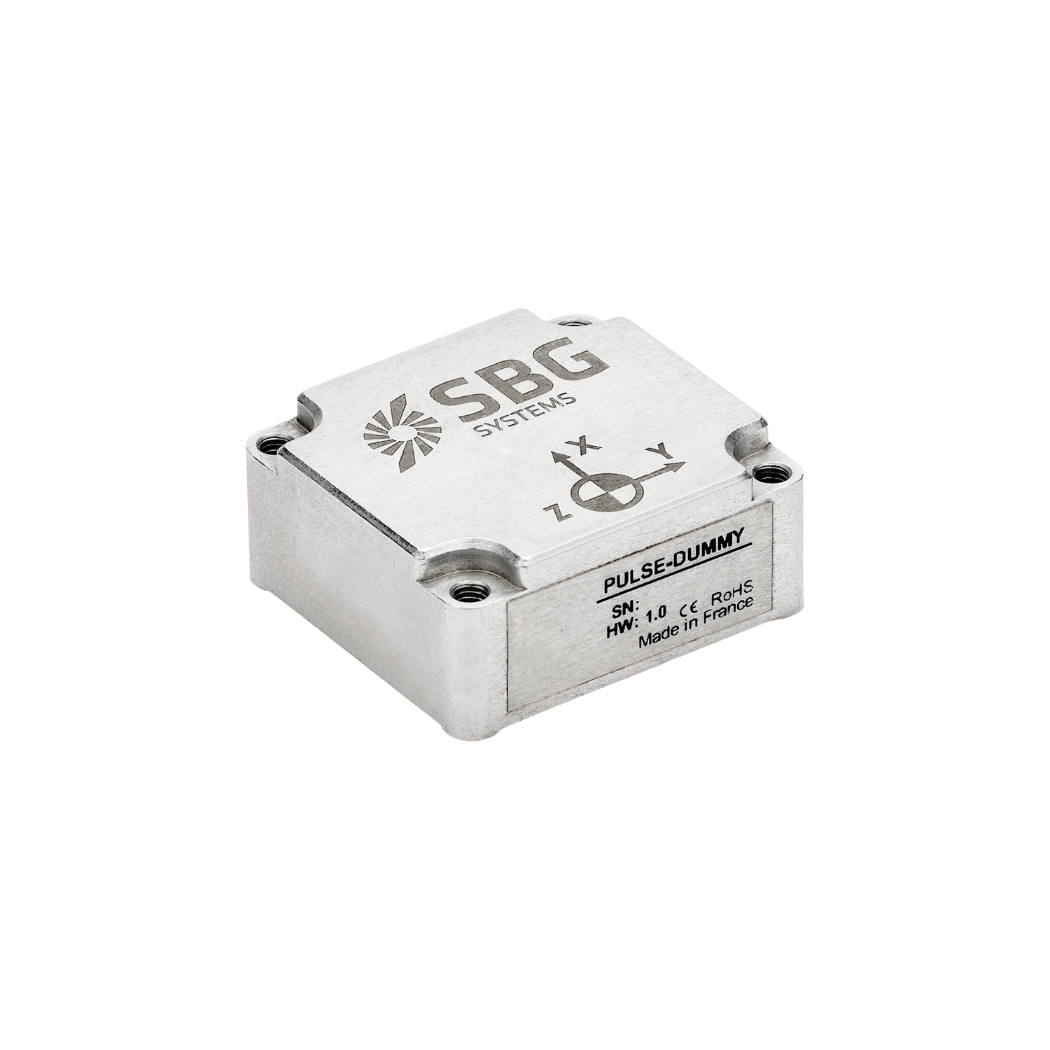

Rugged IMUs for precision munitions guidance

Our IMUs incorporate state-of-the-art MEMS technology with multi-axis gyroscopes and accelerometers, delivering precise angular rate and linear acceleration measurements and efficient filtering and synchronization.

To handle the extreme acceleration forces typical of the launch and flight in guided munitions, our IMUs feature shock-hardened sensor.

Additionally, we employ high-grade thermal compensation to maintain consistent performance across a broad temperature range critical for applications with guided ammunitions that experience different environments.

Solutions for ammunition guidance

Our sensors provide an extremely low latency between motion and output. They are carefully designed with signal conditioning and FIR filtering to deliver high bandwidth while protecting the measurement from vibrations.

Defense applications leaflet

Get our brochure delivered straight to your inbox!

Discover other defense applications

From navigation in GNSS-challenged zones to targeting precision and autonomous system control, our inertial solutions play a vital role in defense. Explore how our high-performance systems support a wide range of military applications, ensuring mission success in even the most challenging conditions.

Do you have questions?

Our team is here to help. Whether you’re looking for technical details, product guidance, or support, we’re ready to assist you every step of the way.

What are the basic parts of ammunition inertial guidance systems?

The basic components of an ammunition inertial guidance system include the Inertial Measurement Unit (IMU), Navigation Computer, Power Supply, Control System, Sensors, and Stabilization Mechanism. The IMU contains accelerometers and gyroscopes to measure the munition’s acceleration and rotational movements. It measures acceleration and rotation, while the navigation computer calculates position and trajectory. Together, these systems ensure precise targeting and flight path adjustments.

What type of inertial system is best suited for short-range precision-guided munitions?

For short-range precision-guided munitions, Tactical-Grade Inertial Navigation Systems (INS) are commonly used. Ours include a MEME-Based IMU due to it’s compact size, lower cost, and sufficient accuracy for short-range applications.

MEMS-based inertial systems offer the right balance between performance, size, and cost for precision-guided munitions at shorter ranges, ensuring accurate targeting while minimizing complexity. Additionally, these systems may be paired with GPS or other sensors to enhance guidance precision.

What is the role of MEMS in a precision guided munition?

MEMS or Micro-Electro-Mechanical Systems play a fondamental role in ensuring accurate guidance and targeting. MEMS gyroscopes and accelerometers measure the munition’s rotational and linear movements, providing critical data on its trajectory and orientation. Moreover, they stabilize the munition during flight by detecting and compensating for any deviations from the intended path.

Concerning Navigation, the data from MEMS sensors is used by the guidance system to calculate the precise position and velocity of the munition, ensuring it follows the correct flight path toward the target.

This technology enables high-precision measurements, which are essential for hitting targets accurately, even in challenging conditions.

SBG Systems MEMS sensors are small and lightweight, making them ideal for integration into the limited space without significantly affecting their weight or aerodynamics.

Overall, these systems enhance the performance and reliability of precision-guided munitions by providing accurate and real-time motion data, crucial for successful targeting and engagement.